About decanter type centrifugal separators

Features of decanter type centrifugal separators

Features of centrifugal dehydrators

- Not susceptible to property changes

- High operability

- Easy to maintain

- Quantitative treatment possible

- Large-capacity treatment

- Abundant experience

- Stable dehydration performance

- Smaller installation space

- Fewer auxiliary appliances

- Hermetic structure and free of offensive odors and toxic gases

Decanter separator mechanismcentrifugal force.

(1) Gravitational field

*In the gravitational field, the liquid gathers in the lower area inside the rotary cylinder. Note: It is not possible to supply a rated treatment quantity.

(2) Centrifugal force field

In the centrifugal force field, the liquid gathers all around the inside of the rotary cylinder, and the solid matter sediments.

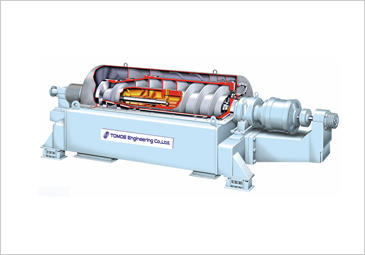

Horizontal decanter (simplified sealing possible)

Contact with the treated substance occurs.

This decanter is capable of continuously separating substances and ensuring stable performance for a long period. It is also easy to operate and can be operated unattended. It has realized significant cost effectiveness and cost reduction. Designed to save space, this decanter requires less installation space. It is used mainly for separation of liquid-liquid mixtures, including separation and dehydration of solid matters, purification and separation of liquid, and classification of solid matters for solid-liquid mixtures, and it ensures efficient treatment of any kind of substance.

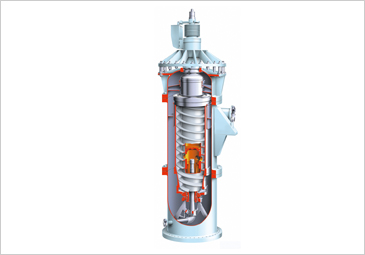

Vertical decanter (pressure-resistant sealing possible)

Its vertical structure, which uses a mechanical seal, ensures thorough hermeticity. In addition, its pressure-resistant structure allows it to separate substances even under high pressure. Requiring less installation space is another advantage of the vertical decanter type centrifugal separator. It is designed to perform efficient separation even under severe conditions and can demonstrate outstanding performance in the deliquoring of resins, solid-liquid separation of slurry containing organic solvents, collection of catalysts, coal liquefaction, and solid-liquid separation of heavy oils, waste plastics, and the like at high temperatures and high pressures in chemical factories. We also offer the HT type centrifugal separator, which is capable of performing treatment at high temperatures up to 400°C.

苏ICP备2020059603号-1

苏ICP备2020059603号-1